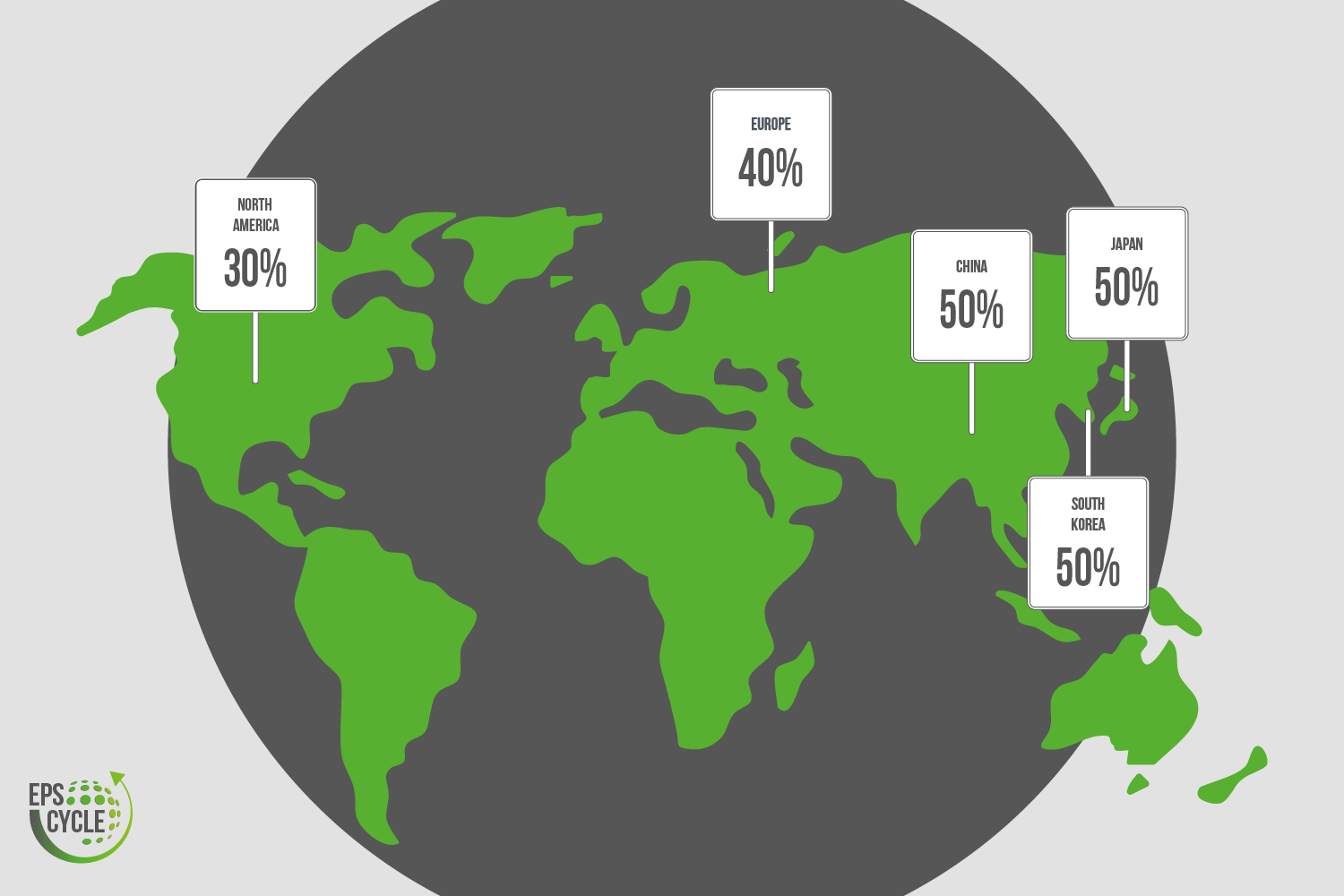

EPS Extensively Recycled Worldwide

New research reveals that EPS (Expanded Polystyrene) is extensively recycled around the globe. With recycling rates exceeding 30% in North America, 40% in Europe, and over 50% in Japan, China, and South Korea, EPS meets the criteria established by the United Nations Environmental Programme.

EPS recycled in 35 countries

Globally, 4.2 billion people in 34 countries have the ability to recycle EPS. This makes EPS the third most recycled packaging material in the world. This is a noteworthy achievement considering less than 2% of all produced packaging material is EPS.

EPS is not just 100% recyclable

In the circular economy, it is not enough for a product to be 100% recyclable. What’s equally important is that recycling actually takes place. The Ellen MacArthur Foundation, an influential international organisation, advances and promotes the circular economy concept by collaborating with businesses, policymakers, and academics. It, alongside the United Nations Environmental Programme, insists that the recyclability of packaging must be demonstrated ‘in practice and at scale’. Based on new data, it’s confirmed that EPS is not only recyclable but it is also being recycled on a large scale.

Seeking circular solutions and aiming to reduce your company’s CO2 footprint?

A network of collection companies, sorters and recyclers is ready to recycle your EPS. Visit our Recycle Directory for a collection of addresses in Denmark, Germany and the Netherlands. We hope that this resource will help make it convenient for you to recycle your EPS and contribute to a more sustainable future.